如果你也在 怎样代写运筹学Operations Research这个学科遇到相关的难题,请随时右上角联系我们的24/7代写客服。假设检验Hypothesis是假设检验是统计学中的一种行为,分析者据此检验有关人口参数的假设。分析师采用的方法取决于所用数据的性质和分析的原因。假设检验是通过使用样本数据来评估假设的合理性。

运筹学(Operation)是近代应用数学的一个分支。它把具体的问题进行数学抽象,然后用像是统计学、数学模型和算法等方法加以解决,以此来寻找复杂问题中的最佳或近似最佳的解答。

二战中运筹学的应用

在二战时期,作战研究被定义为 “一种科学方法,为执行部门提供有关其控制的行动的决策的量化依据”。它的其他名称包括作战分析(英国国防部从1962年开始)和定量管理。

在第二次世界大战期间,英国有近1000名男女从事作战研究。大约有200名作战研究科学家为英国军队工作。

帕特里克-布莱克特在战争期间为几个不同的组织工作。战争初期,在为皇家飞机研究所(RAE)工作时,他建立了一个被称为 “马戏团 “的团队,帮助减少了击落一架敌机所需的防空炮弹数量,从不列颠战役开始时的平均超过20,000发减少到1941年的4,000发。

my-assignmentexpert™ 运筹学Operations Research作业代写,免费提交作业要求, 满意后付款,成绩80\%以下全额退款,安全省心无顾虑。专业硕 博写手团队,所有订单可靠准时,保证 100% 原创。my-assignmentexpert™, 最高质量的运筹学Operations Research作业代写,服务覆盖北美、欧洲、澳洲等 国家。 在代写价格方面,考虑到同学们的经济条件,在保障代写质量的前提下,我们为客户提供最合理的价格。 由于统计Statistics作业种类很多,同时其中的大部分作业在字数上都没有具体要求,因此运筹学Operations Research作业代写的价格不固定。通常在经济学专家查看完作业要求之后会给出报价。作业难度和截止日期对价格也有很大的影响。

想知道您作业确定的价格吗? 免费下单以相关学科的专家能了解具体的要求之后在1-3个小时就提出价格。专家的 报价比上列的价格能便宜好几倍。

my-assignmentexpert™ 为您的留学生涯保驾护航 在运筹学Operations Research作业代写方面已经树立了自己的口碑, 保证靠谱, 高质且原创的应用数学applied math代写服务。我们的专家在运筹学Operations Research代写方面经验极为丰富,各种运筹学Operations Research相关的作业也就用不着 说。

我们提供的假设检验Hypothesis及其相关学科的代写,服务范围广, 其中包括但不限于:

- 商业分析 Business Analysis

- 计算机科学 Computer Science

- 数据挖掘/数据科学/大数据 Data Mining / Data Science / Big Data

- 决策分析 Decision Analytics

- 金融工程 Financial Engineering

- 数据预测 Data Forecasting

- 博弈论 Game Theory

- 地理/地理信息科学 Geography/Geographic Information Science

- 图论 Graph Theory

- 工业工程 Industrial Engineering

- 库存控制 Inventory control

- 数学建模 Mathematical Modeling

- 数学优化 Mathematical Optimization

- 概率和统计 Probability and statistics

- 排队论 Queueing theory

- 社交网络/交通预测模型 Social network/traffic prediction modeling

- 随机过程 Stochastic processes

- 供应链管理 Supply chain management

运筹学代写

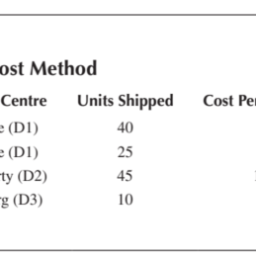

数学代写|运筹学作业代写OPERATIONS RESEARCH代考|CASE STUDY: JOHNSON CONTROLS

The growing market of electric vehicles has increased demand for lithium-ion batteries. Companies, in addition to manufacturing new batteries, are banking on recycling spent batteries in order to fulfil demand. More so with rising concerns of batteries polluting environment and depleting rare earth metals recycling market has grown to be a favourable business proposition. According to a report, battery recycling market is estimated to grow from USD $17.2$ billion in 2020 to USD $23.2$ billion by 2025 . Various leading companies like Exide and Johnson Controls have used this opportunity to augment their businesses.

Johnson Controls supplies lithium ion batteries to various major car manufactures around the world, including BMW, Toyota and GM. With an increasing focus on recycling of used batteries, the company has dedicated a plant in Florence, South Carolina. The operations in this facility reclaim lead from spent batteries and refine them for proper usage in new batteries. This manufacturing process is completed in three stages. In stage 1, after receiving and processing of raw material, the metal is melted in a furnace. In stage 2, the molten metal is cast into a particular type of lead family. The final product can be in the shape of pigs, billets and slugs. As the demand for pigs is maximum, so major portion of production is

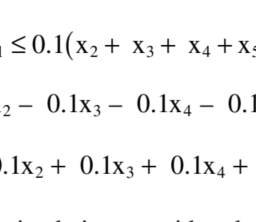

dedicated to the manufacturing of pigs. In last stage, after casting, the cooling is performed, and this would result in the final product. Due to increased demand for recycled lead to be used in automotive batteries, the production manager of the company wants to increase production by minimizing idle time at three stages of production. To understand the minimization of idle time, production schedule of 1 day was broken down into an hourly basis. The plant runs three shifts each for 8 hours. Idle time was found to be a function of production hours. The manager was interested in understanding the number of hours that production should be allocated at every stage so as to minimize idle time. Past data showed that out of total hourly idle time, $15 \%$ was generated at stage $1,24 \%$ and $37 \%$ at stages 2 and 3 , respectively.

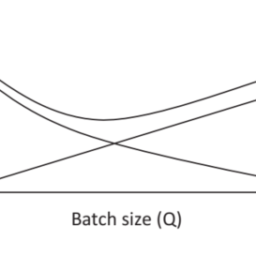

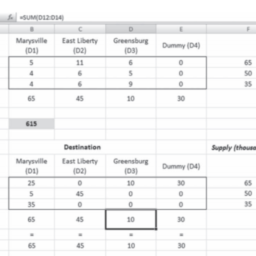

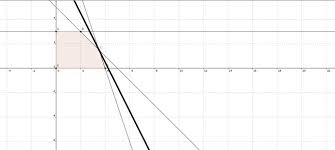

Reduction of idle time was considered to be influenced by the amount of units produced per hour at every stage, inventory produced, number of operators required and utilization of machines. The higher the idle time, the lower would be the production, so it was important to examine the rate of production on an hourly basis. It was estimated that metal to the tune of manufacturing 10,000 units of lead blocks was produced per hour. The second process of casting had the capacity of producing 8,000 casts of lead blocks per hour and, lastly, cooling of 6,000 units could be done on an hourly basis. The production capacity can produce a maximum of 7,000 units of final product per hour. The second constraint that was examined was work-in-process (WIP) inventory produced. Due to the varying capacity of production at every stage, WIP inventory was created that needed to be stored on the shop floor. The material has to be adjusted or moved, resulting in idle time for the next process. Three thousand units of lead block were stored per hour as WIP inventory after stage $1,5,000$ units after stage 2 whereas 4,000 units per hour after stage 3 . Due to the differentiating rate of availability of raw material and production capacity of three stages, the manager has decided to keep a minimum of 4,000 units as inventory. Third, the manager would like to minimize the number of operators required at every stage because a higher number would result in jumbled flow and obstruction among operators resulting in higher idle time. Thus, the manager estimated a minimum of six operators to be applied on the shop floor at any given time. Presently, four, three and six operators are performing at stage 1,2 and 3 respectively on an hourly basis. Finally, machine utilization was studied due to the application of the process of mass production in batches. In this process, the machine keeps on producing till raw material is available irrespective of demand. If a high quantity of raw material is available, then more units would be produced than required, whereas lower availability would result in non-fulfilment of demand. This aspect has an effect on inventory, quantity produced, employees required and also the productivity of machines, which would in turn influence the creation of idle time. For effective production, the manufacturing line should have utilization of minimum $80 \%$. Breaking down machine-wise, it was found that the furnace utilized in stage 1 and casting in stage 2 had utilization rate of $90 \%$, whereas stage 3 machine had utilization rate $100 \%$ on an hourly basis. Taking these four constraints into consideration, formulate a linear model which would minimize idle time.

运筹学代考

数学代写|运筹学作业代写OPERATIONS RESEARCH代考|CASE STUDY: JOHNSON CONTROLS

不断增长的电动汽车市场增加了对锂离子电池的需求。公司除了制造新电池外,还寄希望于回收废旧电池以满足需求。随着对电池污染环境和耗尽稀土金属回收市场的关注日益增加,这一点更是如此,这已成为一个有利的商业主张。据报道,电池回收市场预计将从美元增长17.22020 年 10 亿美元23.2到 2025 年 10 亿。Exide 和 Johnson Controls 等多家领先公司都利用这个机会扩大了业务。

江森自控为全球各大汽车制造商供应锂离子电池,包括宝马、丰田和通用汽车。随着越来越关注废旧电池的回收,该公司在南卡罗来纳州的佛罗伦萨设立了一家工厂。该设施的操作从废旧电池中回收铅并对其进行提炼,以便在新电池中正确使用。该制造过程分三个阶段完成。在第一阶段,在接收和处理原材料后,金属在熔炉中熔化。在第 2 阶段,熔融金属被铸造成特定类型的铅族。最终产品可以是猪、坯料和蛞蝓的形状。由于对生猪的需求最大,所以生产的主要部分是

致力于猪的生产。在最后阶段,在铸造后进行冷却,这将产生最终产品。由于对用于汽车电池的再生铅的需求增加,该公司的生产经理希望通过最大限度地减少三个生产阶段的闲置时间来提高产量。为了了解空闲时间的最小化,将 1 天的生产计划分解为每小时。该工厂运行三班倒,每班工作 8 小时。发现空闲时间是生产时间的函数。经理有兴趣了解每个阶段应分配生产的小时数,以最大限度地减少空闲时间。过去的数据显示,在每小时的总空闲时间中,15%在阶段生成1,24%和37%分别在第 2 和第 3 阶段。

空闲时间的减少被认为受到每个阶段每小时生产的单位数量、生产的库存、所需的操作员数量和机器利用率的影响。闲置时间越长,产量就越低,因此以每小时为单位检查生产率很重要。据估计,每小时可生产 10,000 个铅块的金属。第二道铸造工艺具有每小时生产 8,000 个铅块铸件的能力,最后可以每小时完成 6,000 个铅块的冷却。生产能力每小时最多可生产 7,000 件最终产品。检查的第二个约束是在制品在一世磷产生的库存。由于每个阶段的生产能力不同,创建了需要在车间存储的 WIP 库存。必须调整或移动材料,从而导致下一个过程的空闲时间。阶段后每小时存储 3000 单位铅块作为 WIP 库存1,5,000第 2 阶段后的单位,而第 3 阶段后每小时 4,000 单位。由于三个阶段的原材料可用性和生产能力的差异化率,经理决定至少保留4,000个单位作为库存。第三,管理人员希望尽量减少每个阶段所需的操作员数量,因为数量过多会导致操作员之间的混乱流动和阻塞,从而导致更长的空闲时间。因此,经理估计在任何给定时间至少有六名操作员将应用于车间。目前,四个、三个和六个操作员分别在第 1、2 和 3 阶段按小时进行表演。最后,由于批量生产过程的应用,对机器利用率进行了研究。在这个过程中,无论需求如何,机器都会继续生产直到原材料可用。如果有大量原材料可用,则生产的单位将多于需要,而较低的可用性将导致无法满足需求。这方面会影响库存、生产数量、所需员工以及机器的生产力,进而影响空闲时间的产生。为了有效生产,生产线应具有最低的利用率 这反过来又会影响空闲时间的产生。为了有效生产,生产线应具有最低的利用率 这反过来又会影响空闲时间的产生。为了有效生产,生产线应具有最低的利用率80%. 机器分解发现,第一阶段使用的炉子和第二阶段的铸件的利用率为90%,而第 3 阶段的机器有利用率100%按小时计算。考虑到这四个约束,制定一个线性模型,将空闲时间最小化。