如果你也在 怎样代写运筹学Operations Research这个学科遇到相关的难题,请随时右上角联系我们的24/7代写客服。假设检验Hypothesis是假设检验是统计学中的一种行为,分析者据此检验有关人口参数的假设。分析师采用的方法取决于所用数据的性质和分析的原因。假设检验是通过使用样本数据来评估假设的合理性。

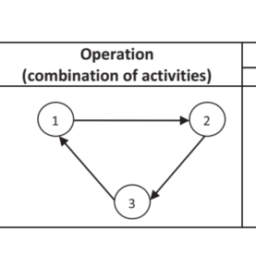

运筹学(Operation)是近代应用数学的一个分支。它把具体的问题进行数学抽象,然后用像是统计学、数学模型和算法等方法加以解决,以此来寻找复杂问题中的最佳或近似最佳的解答。

二战中运筹学的应用

在二战时期,作战研究被定义为 “一种科学方法,为执行部门提供有关其控制的行动的决策的量化依据”。它的其他名称包括作战分析(英国国防部从1962年开始)和定量管理。

在第二次世界大战期间,英国有近1000名男女从事作战研究。大约有200名作战研究科学家为英国军队工作。

帕特里克-布莱克特在战争期间为几个不同的组织工作。战争初期,在为皇家飞机研究所(RAE)工作时,他建立了一个被称为 “马戏团 “的团队,帮助减少了击落一架敌机所需的防空炮弹数量,从不列颠战役开始时的平均超过20,000发减少到1941年的4,000发。

my-assignmentexpert™ 运筹学Operations Research作业代写,免费提交作业要求, 满意后付款,成绩80\%以下全额退款,安全省心无顾虑。专业硕 博写手团队,所有订单可靠准时,保证 100% 原创。my-assignmentexpert™, 最高质量的运筹学Operations Research作业代写,服务覆盖北美、欧洲、澳洲等 国家。 在代写价格方面,考虑到同学们的经济条件,在保障代写质量的前提下,我们为客户提供最合理的价格。 由于统计Statistics作业种类很多,同时其中的大部分作业在字数上都没有具体要求,因此运筹学Operations Research作业代写的价格不固定。通常在经济学专家查看完作业要求之后会给出报价。作业难度和截止日期对价格也有很大的影响。

想知道您作业确定的价格吗? 免费下单以相关学科的专家能了解具体的要求之后在1-3个小时就提出价格。专家的 报价比上列的价格能便宜好几倍。

my-assignmentexpert™ 为您的留学生涯保驾护航 在运筹学Operations Research作业代写方面已经树立了自己的口碑, 保证靠谱, 高质且原创的应用数学applied math代写服务。我们的专家在运筹学Operations Research代写方面经验极为丰富,各种运筹学Operations Research相关的作业也就用不着 说。

我们提供的假设检验Hypothesis及其相关学科的代写,服务范围广, 其中包括但不限于:

- 商业分析 Business Analysis

- 计算机科学 Computer Science

- 数据挖掘/数据科学/大数据 Data Mining / Data Science / Big Data

- 决策分析 Decision Analytics

- 金融工程 Financial Engineering

- 数据预测 Data Forecasting

- 博弈论 Game Theory

- 地理/地理信息科学 Geography/Geographic Information Science

- 图论 Graph Theory

- 工业工程 Industrial Engineering

- 库存控制 Inventory control

- 数学建模 Mathematical Modeling

- 数学优化 Mathematical Optimization

- 概率和统计 Probability and statistics

- 排队论 Queueing theory

- 社交网络/交通预测模型 Social network/traffic prediction modeling

- 随机过程 Stochastic processes

- 供应链管理 Supply chain management

运筹学代写

数学代写|运筹学作业代写OPERATIONS RESEARCH代考|CASE STUDY: MODERN FOODS INDIA LIMITED

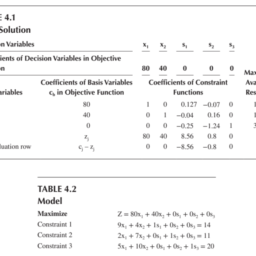

Modern Foods India Limited (MFIL) is the second largest bread manufacturer in the country. Bread as a food has seen increased adoption among urban Indians. The company is involved in producing three different varieties of bread: wheat based (A), wholegrain (B) and multi-grain (C). To increase its market share and become a leading player, the company intends to increase the volume of each variety and also keep the cost down. The present process applies batch production system where each machine produces in bulk of one type of bread. For instance, the first process is of mixing ingredients. As some of the ingredients are particular to a particular type of bread, the producer mixes certain quantity of them for the production of a batch of breads. Then this batch moves to second machine carrying out process of moulding and, finally, to oven. The batch type of production system results in building of lot of work-in-process (WIP) inventory which adds to cost of production and thus effecting profitability. Application of the current system allows producer to earn profit of $\$ 1.0$, $\$ 1.2$ and $\$ 1.1$ on per kilogram of bread.

With increase in demand for all types of breads, producers intend to shift operations to a combination of batch and line production known as hybrid system. Such a shift results in a reduction of non-value added activities or wastes. Management decided to further reduce wastes by applying various lean manufacturing techniques.

Three of such techniques, namely (i) modification of push system (batch) to pull system (hybrid); (ii) reduction in change over time and (iii) improvement in preventive maintenance method, were identified after thorough brainstorming with shop floor managers and workers. It was also estimated that at least $10 \%$ improvement in profits be achieved across all three types of breads as a result of implementation of selecting lean manufacturing techniques. To find whether objective of obtaining potential gains from implementing such techniques was achieved, a model was constructed which compared estimated results of modified system with the current system. Details of three techniques with regard to current and modified system are described as under. The system operated in three shifts of 8 hours each for 30 days a month. The data was recorded for a production schedule which was formed for 1 week and then created or modified again depending on customer demand.

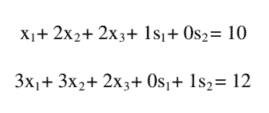

The performance of push and pull system was evaluated through analysis of WIP inventory. The pull system is considered to be more effective in reducing inventory as in this system production is initiated only when a customer’s order is received, whereas in the push system, products are manufactured without estimation of demand. Current system at the plant suggested an average inventory equivalent of $0.58,0.2$ and $0.36$ days for $\mathrm{A}, \mathrm{B}$ and $\mathrm{C}$, respectively. Past data showed piling of stocks at the end of the month equivalent to inventory of 15 days. With modification to the hybrid system, optimistic but realistic inventory values were estimated to reduce to $0.45,0.12$ and $0.25$ days of three types of products. Also, maximum inventory should be reduced to 09 days at the end of month. Collecting weekly data indicated change over time under the current system to be on an average of 15,120 and 90 minutes, respectively, for A, B and C. The maximum allowed change over time for such a system was 800 minutes. Application of lean manufacturing technique resulting in reduction of such time should result in reduction of maximum change over time to 200 minutes and 5,20 and 20 minutes for three products. Finally, production schedule data indicated that out of a total 1,440 minutes allocated for preventive maintenance of entire process, an average of 90,70 and 50 minutes is attributed to production of $A, B$ and $C$ type of bread. Suggested values for the modified model were 36,20 and 15 minutes out of a total of 240 minutes.

i. Is modified model feasible? Infer the difference with original model.

ii. Estimate the maximum and minimum values of profits that could be earned from production of three types of breads.

iii. What would be a feasible range of inventory level, change over time and preventive maintenance time within which optimal profits could be achieved?

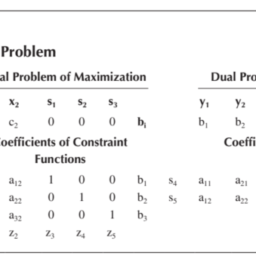

iv. Construct dual model for both original and modified models and compare the results. Identify shadow prices by comparing the dual solution of the modified model with its primal form.

v. Average combined demand of three types of bread per month was calculated as 48,000 units. Infer changes to both models that would occur due to addition of this constraint.

运筹学代考

数学代写|运筹学作业代写OPERATIONS RESEARCH代考|CASE STUDY: MODERN FOODS INDIA LIMITED

现代食品印度有限公司米F一世一世是全国第二大面包生产商。面包作为一种食物在印度城市中得到了越来越多的采用。该公司涉及生产三种不同品种的面包:小麦面包一种, 全麦乙和多粒C. 为了增加其市场份额并成为领先者,该公司打算增加每个品种的数量并降低成本。本工艺采用批量生产系统,其中每台机器批量生产一种类型的面包。例如,第一个过程是混合成分。由于某些成分是特定类型的面包所特有的,因此生产者将一定数量的成分混合在一起以生产一批面包。然后这批物料移至第二台机器进行成型过程,最后移至烘箱。批量生产系统导致大量在制品的构建在一世磷库存增加了生产成本,从而影响了盈利能力。当前系统的应用允许生产者赚取利润$1.0,$1.2和$1.1每公斤面包。

随着对所有类型面包需求的增加,生产商打算将运营转移到批量和生产线相结合的生产方式,即混合系统。这种转变导致非增值活动或浪费的减少。管理层决定通过应用各种精益制造技术进一步减少浪费。

其中三种技术,即一世推送系统改造b一种吨CH拉系统H和br一世d;一世一世随着时间的推移减少变化和一世一世一世在与车间经理和工人进行彻底的头脑风暴后确定了预防性维护方法的改进。据估计,至少10%由于选择精益制造技术,所有三种类型的面包都可以提高利润。为了确定是否实现了从实施这些技术中获得潜在收益的目标,构建了一个模型,将修改后的系统的估计结果与当前系统进行了比较。关于当前和修改后的系统的三种技术的详细信息如下所述。该系统以每月 30 天、每班 8 小时的三班倒运行。这些数据被记录为一个生产计划,该计划为期 1 周,然后根据客户需求再次创建或修改。

通过分析 WIP 库存来评估推拉系统的性能。拉式系统被认为在减少库存方面更有效,因为在该系统中,只有在收到客户订单时才开始生产,而在推式系统中,产品是在没有估计需求的情况下制造的。该工厂的当前系统建议平均库存相当于0.58,0.2和0.36天数一种,乙和C, 分别。过去的数据显示,月底的库存堆积相当于 15 天的库存。随着对混合系统的修改,乐观但现实的库存值估计会降低到0.45,0.12和0.25天三类产品。此外,最大库存应减少到月底的 09 天。每周收集的数据表明,在当前系统下,A、B 和 C 的平均时间变化分别为 15,120 和 90 分钟。这种系统的最大允许时间变化为 800 分钟。精益制造技术的应用导致这种时间的减少应该导致随着时间的推移最大变化减少到 200 分钟和 5,20 和 20 分钟的三种产品。最后,生产计划数据表明,在分配给整个过程的预防性维护的总共 1,440 分钟中,平均有 90,70 和 50 分钟用于生产一种,乙和C面包的类型。修改后的模型的建议值为 36,20 和 15 分钟(总共 240 分钟)。

一世。修改后的模型可行吗?推断与原始模型的差异。

ii. 估计生产三种面包所能获得的利润的最大值和最小值。

iii. 可以实现最佳利润的库存水平、随时间变化和预防性维护时间的可行范围是多少?

iv. 为原始模型和修改模型构建对偶模型并比较结果。通过比较修正模型的对偶解与其原始形式来识别影子价格。

v. 三种面包每月的平均需求量计算为 48,000 单位。推断由于添加此约束而将发生的两个模型的更改。